So you want to go solar, but can’t decide between Lithium Iron Solar Batteries and Lead Acid Batteries. What’s the big deal?

Lithium Iron vs Lead acid batteries? In this post, we’ll discuss the difference between the two solar batteries:

- Small size and lightweight

- Battery usable capacity

- Long cycle life

- Lifepo4 is safer than lead acid:

- Lead-acid batteries

- Lifepo4 battery characteristics

So you have heard of Lithium Iron phosphate (lifepo4 or LFP) batteries and are wondering whether they are worth the rage and raving?

Here are a few differences between lead acid batteries and lithium phosphate batteries to help you make a decision.

Lithium Solar Batteries Are Small in size and lightweight

Lead acid batteries take up more space than lithium iron phosphate batteries and when are mote difficult to wire up when you are connecting a large bank. The combined weight and volume occupied by lead acid batteries in a bank greater than a lifepo4 of equivalent capacity.

Solar Battery usable capacity

Below we can see that only a specific percentage of the battery can be used. We call this the Depth of discharge.

So a 100ah Lead acid is only 50-60% usable. Meaning it can be dropped to 40 or 50%.

Maximum daily depth of discharge (DoD) allowed **

-

Lithium-iron Phosphate = 80 to 90%

-

Lead-acid AGM = 15 to 30%

-

Lead-acid Gel = 20 to 40%

Lithium Solar Batteries Have a Long cycle life

Lithium battery cycle life can be over 5000 times, which means a 10 to 20 year service life but the traditional lead-acid battery can be less than 1000 times which means 3 to 5 years.

A Lithium Iron battery is more efficient with energy when it uses it to charge or when it is running a load and therefore discharging. It is 90% efficient that a lead acid which is 70% efficient.

Lithium Solar Batteries / Lifepo4 are safer than lead acid

Lead-acid batteries contain heavy metals such as lead which is dangerous to the environment and wildlife. The battery will leak over time. Sulphuric acid Leaks may cause equipment corrosion and personal injury. Lithium iron phosphate batteries are safer as they do not contain any heavy metals and are non-toxic. The battery does not explode or ignite when punctured, overcharged or short circuited.

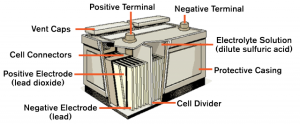

Lead-acid batteries

- The lead-acid battery does not fare well on demanding loads and grows weaker if the demands are constantly high.

- The battery is prone to self discharge when idle and can end up useless.

- It has problems in low-temperatures due to electrolytes freezing. The chemical reaction needed to create lead oxide cannot occur.

- The performance is greatly reduced over time.

- The batteries has fewer cycles and can not be charged and discharged indefinitely.

- Risk of explosion whem being overcharged.

- Leakages of acid and discharging of fumes or vapours.

- Short life span and low durability.

Lithium Solar Batteries/ Lifepo4 battery characteristics

- The battery can be charged and discharged at any time.

- The battery self-discharge is low, monthly self-discharge is less than 1%, the battery can be stored for a long time without discharging substantially.

- Uses a BMS system to charge and equalise batteries so they charge at an equal rate. Lead acid bayteries do not charge equally on most inverters and this damages them even when when they are not used much.

- Fast charging. Charges at a faster and higher rate than lead acid batteries.

- Discharge is more stable and does not drop in the way that a lead acid drops when it reaches certain voltages.

Lead acid battery technology is still improving and so we have not seen the end of lead acid batteries yet nor are we saying that LiFePo4 is the peak of battery technology. There is more to come. Lithium Iron batteries remain the most affordable batteries and value for money from an investment point. They are used by manufactures of electric cars all over the world including Tesla automobiles.

Take a look at our range of Lithium Iron batteries by clicking shop on our menu.

) and the Hz button is pressed. The DMM is ready to measure duty cycle when a percent sign (%) appears in the right side of the multimeter’s display.

) and the Hz button is pressed. The DMM is ready to measure duty cycle when a percent sign (%) appears in the right side of the multimeter’s display. ) to toggle between POSITIVE time and NEGATIVE time percent voltage measurement. Note: The button used varies by digital multimeter. Refer to you model’s user manual for specific instructions.

) to toggle between POSITIVE time and NEGATIVE time percent voltage measurement. Note: The button used varies by digital multimeter. Refer to you model’s user manual for specific instructions.